I. Overview of Nigeria

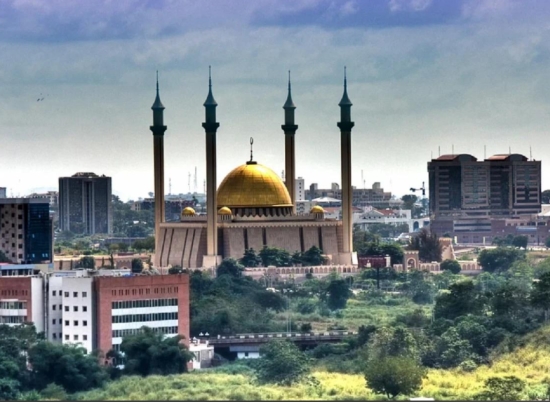

It has a land area of 923768 square kilometers, a population of 227 million (2024), an official language of English, a capital of Abuja, and a total GDP of 374.9 billion US dollars in 2023, with a per capita GDP of 1690 US dollars. Rich in mineral resources, the petroleum industry is the pillar of the national economy.

Since its independence, Nigeria has always regarded industrialization as a strategic path to achieve sustainable economic growth. Over the past decade, successive governments have taken many initiatives to achieve this goal, launching the Nigerian Industrial Revolution Plan (NIRP), which aims to promote economic diversification and promote the growth of agricultural processing and petrochemical sectors in manufacturing industry. The “anchor borrower program” was implemented to provide low-interest financing for agricultural processing enterprises and connect them with small farmers to ensure a stable supply of raw materials; in addition, special economic zones and industrial parks were introduced to attract investment by providing tax breaks, infrastructure subsidies, simplified regulatory procedures and other targeted incentives.

Nigeria remains one of the most attractive countries in Africa for investment. As the most populous country in Africa, Nigeria has a growing middle class, coupled with various incentive policies introduced by the government, the potential for the revival of manufacturing industry is huge. In addition, Nigeria is rich in natural resources and has a good geographical location, which is the gateway to the African market.

II. Overview of Nigerian Iron and Steel

Nigeria’s steel demand is highly dependent on imports. In 2023, the crude steel output is only 1.19 million tons. In 2024, the crude steel output is about 200,0000 tons. The actual demand is more than 10 million tons. The annual import value is more than 4 billion US dollars. The annual import of steel is more than 1.5 million tons, indicating that the steel demand is highly dependent on imports. In order to improve the self-sufficiency rate, the federal government is actively attracting foreign direct investment into the steel sector and is committed to achieving the target of 10 million tons of steel per year by 2030.

Nigeria is rich in mineral resources, including oil, natural gas, iron ore and coal, which provide important support for economic development, but the steel industry contributes less to the national economy. From 2000 to 2023, Nigeria’s economic growth has experienced three stages of rapid growth, steady development and slow growth, in which the economic structure is highly dependent on resource-based industries such as oil and natural gas, accounting for 6% of GDP, while the steel industry contributes less to GDP, accounting for about 0.2%.

In recent years, Nigeria’s iron and steel industry is undergoing structural changes, local production capacity is gradually released, and policy support and foreign investment jointly promote industrial upgrading. Despite infrastructure and technology bottlenecks, the country is accelerating its transformation from a major steel importer to a regional manufacturing center, relying on abundant iron ore resources and huge market demand.

III. Major iron and steel enterprises in Nigeria

The steel complex in Nigeria consists mainly of Ajaokuta Steel (Ajaokuta Steel Company, ASC) and Delta Steel (Delta Steel Company, DSC). At present, the two steel mills are not operating normally. The output is still dominated by small and medium-sized rolling mills.

Although the Nigerian government has been committed to developing the steel industry for many years, many projects have failed to make substantial progress due to the shortage of raw materials and other problems. At present, iron and steel production is mainly dominated by private enterprises, while state-owned enterprises are facing difficulties for various reasons.

From the perspective of production capacity, private steel enterprises occupy a dominant position in local steel production. As the largest local steel enterprise in Nigeria at present, KAM Steel has an annual crude steel production capacity of 600,000 tons and a rolling steel production capacity of 150,000 tons. With its large production capacity, KAM Steel has certain advantages in market competition and can meet the needs of large-scale customers. It has a wide range of customer groups in construction, manufacturing and other fields. With an annual production capacity of 500,000 tons, African Foundries Limited mainly produces steel billets and rebars, which has a high reputation and market share in the Nigerian construction market, and its stable capacity supply provides a guarantee for the smooth progress of local construction projects.

In terms of products, the product variety and quality of enterprises have become the key factors in competition. By continuously introducing advanced production equipment and technology, KAM Steel can not only produce ordinary construction steel, but also produce some high-end special steel to meet the needs of different customers. African Foundries Limited pays attention to the improvement of product quality, and its billets and steel bars are recognized by the market for their stable quality and excellent performance, thus establishing a good brand image in the construction market. Enterprises such as Sunflag Steel Nigeria and Universal Steel Limited are also constantly optimizing product mix and improving product quality in order to enhance their market competitiveness.

1. State-owned steel enterprises: Nigerian state-owned steel enterprises can be traced back to 1979, when the Nigerian government set the goal of building a steel complex. The steel complex consists mainly of Ajaokuta Steel (Ajaokuta Steel Company, ASC) and Delta Steel (Delta Steel Company, DSC). At present, the two steel mills are not operating normally, specifically:

(1) Ajaokuta Steel (ASC)

Designed production capacity: ASC is produced by blast furnace, with an annual output of 1.3 million tons of liquid steel in the first stage, 2.6 million tons in the second stage and 5.2 million tons in the third stage.

Status: Due to insufficient supply of iron ore and inefficient management, it has not been formally put into production so far. In 2005, ASC was handed over to Global Steel Holdings Nigeria Limited (GHNL), but the Nigerian government terminated its operation due to slow progress. In 2024, the government plans to resume production through privatization.

(2) Delta Steel Corporation (DSC)

Design capacity: The planned capacity of DSC is 1 million tons/year, and the direct reduction technology is adopted.

Status: Due to the shortage of raw materials and energy problems, some facilities of DSC have been suspended. It was privatized and sold to India Global Infrastructure Nigeria (GINL) in 2005. GINL also acquired National Iron Ore Mining Company (NIOMCO), which changed ownership several times between 2005 and 2012 and is now managed by Premium Steel and Mines Limited. However, it has not yet resumed operations, and the production facilities have been sold.

2. Private steel enterprises: Private steel enterprises in Nigeria play a dominant role in crude steel production. It is estimated that there are dozens of steel enterprises, including:

(1) KAM Steel: Located in Ogun State in the southwest and Kaduna State in the north of Nigeria, KAM Steel is currently the largest indigenous steel company in Nigeria. The annual crude steel production capacity is 600,000 tons, and the rolling steel production capacity is 150,000 tons.

(2)African Foundries Limited: The company is located in Ogun State and mainly produces steel billets and rebars with an annual production capacity of 500,000 tons.

(3)Sunflag Steel Nigeria: The company is located in Lagos State in the southwest of Nigeria and mainly produces steel billets and rolled steel with an annual production capacity of about 150,000 tons.

(4)Universal Steel Limited: The company is located in Lagos State and mainly produces hot rolling with an annual capacity of 100,000 tons.

3. Investment of Chinese steel enterprises in Nigeria:

With the layout of Chinese investment enterprises such as Kaduna Steel Plant and Yongxing Steel (annual capacity of 500000 tons), local production capacity is gradually released. Data show that in 2024, Nigeria’s steel imports fell by 12% year-on-year, and the market share of local products increased to 35%.

The two countries have a long history of cooperation in the field of steel. Since the signing of the protocol between the two governments in 1997, China Metallurgical Construction Group has been working to resume production at the Delta Steel Plant in Nigeria. Through technology export and management cooperation, the production capacity of the steel plant has been gradually restored to 100%, which has become a successful case of industrial cooperation between China and Nepal.

Major Chinese-funded steel plants in Nigeria include:

(1) Yongxing Steel, from Fujian Province, China, located in Edo State, Nigeria;

(2) Hongxing Zhongyuan Steel, from Fujian Province, China, with a plant located in Abia State, Nigeria;

(3) Yulong Steel Pipe, from Jiangsu Province, China, factory located in Lagos State, Nigeria;

(4) Baoyao Steel, from Shanghai, China, with a plant located in Chris River State, Nigeria;

(5) Tung Group, from Hong Kong, China, located in Ogun State, Nigeria.

IV. Steel demand in Nigeria

Nigeria is the most populous country in Africa. According to the data of the World Bank, the resident population will reach 228 million in 2023. The urbanization rate of Nigeria has also reached 60%. Factors such as land area, geographical location, population and economy determine that Nigeria has certain development potential, and it is also the key driver of the outbreak of steel demand. Nigeria’s domestic demand for steel is mainly concentrated in construction, transportation, energy and other fields. With the advancement of infrastructure construction and the acceleration of industrialization, the consumption of iron and steel is increasing.

The steel market in Nigeria has great potential. Its steel demand mainly comes from infrastructure construction and manufacturing, which account for more than 60% of consumption. With the steady progress of major projects such as the Lagos-Kano Railway, Nigeria’s steel consumption is expected to be at least 3 million tons by 2030.

In order to promote the innovation and development of Nigeria’s steel industry, the government has formulated the National Industrial Revolution Plan, which aims to actively attract foreign investment through privatization, tax relief and infrastructure investment.

(1)Capital constructio:

The “2030 Industrialization Plan” will launch major projects such as coastal railways and trans-regional highway networks in 2025. The Nigerian government has been committed to improving the domestic infrastructure and has increased investment in transportation, energy and other fields. In terms of transportation, road construction projects are constantly advancing, and new and expanded highway networks require a large amount of steel for bridge construction, road guardrails and other facilities; railway construction is also gradually carried out, and steel is indispensable for rail laying, station construction and railway bridge construction. In the energy sector, the oil and gas industry is a pillar industry in Nigeria. With the further development of oil and gas resources, the demand for steel continues to grow in the construction of drilling platforms, pipeline laying and related supporting facilities.

Large-scale housing construction and road reconstruction projects in Nigeria have made building materials the largest import category, among which cement, steel, aluminum alloy doors and windows and decorative materials are in the strongest demand. In terms of demand characteristics, as infrastructure projects are mostly concentrated in Lagos, Abuja and other large cities, the demand for building materials is large and the delivery is required to be timely; at the same time, considering the local high temperature and rainy climate, building materials with moisture-proof and corrosion-resistant properties are more popular. In terms of purchasing preference, Nigerian purchasers prefer mid-end products with high cost performance, are more sensitive to price, and prefer small batch and multi-frequency purchasing to reduce inventory pressure. For example, the demand for hot-dip galvanized steel pipes has surged in construction scaffolding and water supply pipeline projects because of their corrosion resistance. Lightweight partition board has become the preferred material for residential construction because of its convenient construction and low cost.

(2) Manufacturing industry:

Although the manufacturing industry is still in its infancy, it has shown a good momentum of development in recent years, and the demand for steel is gradually increasing. With the start of projects such as “steel + new energy + equipment manufacturing” industrial complex in Ogun State, the demand for high-strength steel structure, industrial plate and other steel products in manufacturing industry has increased sharply. In the field of automobile manufacturing, although Nigeria’s automobile industry is relatively small, with the development of local automobile brands and the entry of international automobile manufacturers, the demand for automotive steel has begun to emerge, such as body sheet, engine parts steel and so on. Machinery and equipment manufacturing industry also needs a large number of steel as raw materials for the production of various machinery and equipment, such as agricultural machinery, engineering machinery and so on.

V. Strengths and Weaknesses of Nigerian Steel

1. Advantages

(1) Resource advantages:

As a gateway country in West Africa, Nigeria has potential advantages in the process of industrialization by virtue of its abundant mineral resources, especially iron ore reserves. Nigeria’s iron ore is mainly magnetite and hematite, with an average iron grade of 36% -41%. At present, the proven reserves are about 1 billion tons and the estimated reserves are more than 2 billion tons. In recent years, some new progress has been made in the development of iron and steel industry in Nigeria.

(2) Geographical and population advantages:

In addition, the country has a superior geographical location, which can radiate the market of more than 200 million people in West Africa and become a regional steel export hub.

(3) Policy advantages

National Industrial Revolution Plan (NIRP), Industrialization Plan 2030, etc. The federal government is actively attracting foreign direct investment in the steel sector and is committed to achieving the target of 10 million tons of steel per year by 2030. In December 2024, the Nigerian government decided to privatize the state-owned Ajaokuta Iron and Steel Company (Ajaokuta Steel Company, ASC) and its related iron ore mines in Itapei in order to attract investors and achieve long-term operation. This move is expected not only to revive long-stagnant steel production, but also to inject new vitality into the revival of the steel industry.

2.Insufficient

(1) Although it has the seventh largest iron ore reserves in the world, its development rate is less than 10%, and it is in urgent need of foreign investment and technological upgrading. Nigeria’s steel industry is undergoing structural changes, with the gradual release of local production capacity, policy support and foreign investment to jointly promote industrial upgrading.

More: https://www.sinosteel-pipe.com/en/overview-of-nigerian-iron-and-steel-industry.html