Material science continues to evolve as industries demand lighter, stronger, and more efficient solutions. Graphite oxide (GO) has emerged as one of the most versatile materials supporting this transition.

According to data compiled from materials research publications and market analysis platforms such as Statista, advanced carbon-based materials are expected to support a global market exceeding USD 20 billion by the end of this decade, driven largely by energy storage, electronics, and protective coatings.

This growth highlights the increasing reliance on GO to enhance performance while controlling costs.

GO stands out because it bridges the gap between traditional graphite and advanced two-dimensional carbon materials. Its chemical structure allows engineers to tune properties for specific applications. As a result, industries now use GO to solve challenges that older materials cannot address effectively.

What Is Graphite Oxide (GO) and Why Does It Matter?

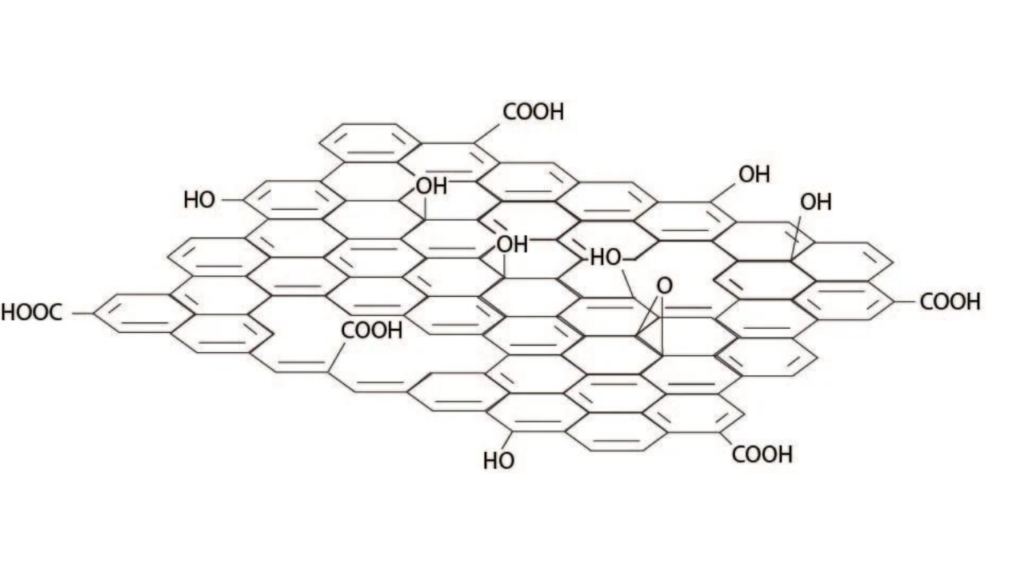

Graphite oxide forms when graphite undergoes controlled oxidation. This process introduces oxygen-containing functional groups across the layered carbon structure. These groups change how the material interacts with electricity, heat, and chemicals.

Because of this modification, GO disperses easily in liquids and bonds well with polymers, metals, and ceramics. This compatibility makes it valuable for large-scale manufacturing. At the same time, its layered structure preserves many advantages of graphite, such as strength and stability. These combined features explain why GO plays a growing role across multiple industries.

Structural Properties That Enable Broad Applications

The layered structure of GO creates a balance between rigidity and flexibility. Each layer remains thin, yet the material maintains mechanical integrity when integrated into composites or coatings.

Oxygen functional groups increase surface activity. This feature improves adhesion and chemical interaction. As a result, GO performs well in systems that require strong bonding and uniform dispersion. These structural advantages form the foundation for its use in energy devices, electronic components, and protective surfaces.

Role of Graphite Oxide in Energy Storage Systems

Energy storage technologies depend on materials that support fast charge transfer and long cycle life. It contributes by increasing the active surface area and improving electrolyte interaction.

In batteries, GO enhances ion movement between electrodes. This improvement supports faster charging and better capacity retention. Moreover, its layered structure accommodates structural changes during cycling. Therefore, devices experience reduced degradation over time. These benefits make GO a practical material for modern energy storage solutions.

Supporting Advanced Electronics and Functional Devices

Electronics continue to shrink while performance expectations rise. It helps address this challenge by offering tunable electrical properties.

Because oxidation alters conductivity, engineers can adjust GO behavior for specific functions. It supports applications such as sensors, flexible circuits, and printed electronics. Furthermore, its compatibility with solution-based processing allows cost-effective fabrication. This advantage supports scalable electronics manufacturing without sacrificing performance.

Improving Performance in Functional and Protective Coatings

Coatings must protect surfaces while maintaining durability under stress. Graphite oxide strengthens coatings by improving barrier properties and mechanical resistance.

When added to protective layers, it reduces permeability to moisture and gases. This improvement slows corrosion and material degradation. Additionally, the layered structure enhances scratch resistance and surface stability. These qualities make GO valuable in industrial, marine, and infrastructure coatings.

Graphite Oxide in Composite Materials

Composite systems rely on fillers that enhance strength without adding excessive weight. Its surface chemistry promotes strong bonding with polymers and resins. This bonding improves load transfer across the composite. As a result, materials gain higher tensile strength and improved durability. Industries such as construction and transportation increasingly use GO to improve composite performance while maintaining lightweight designs.

Practical Tips for Working with Graphite Oxide

Successful use of graphite oxide depends on proper handling and formulation. First, uniform dispersion remains essential. Proper mixing techniques prevent agglomeration and ensure consistent performance.

Second, material concentration requires careful control. Low concentrations often deliver significant improvements without affecting processability. Third, compatibility testing helps optimize bonding with host materials. Following these steps allows manufacturers to achieve reliable results across applications.

Real-World Applications Driving Industry Adoption

GO already supports real-world solutions. In energy systems, it improves battery efficiency and operational stability. In electronics, it enables flexible components and functional coatings for circuits.

Industrial coatings benefit from improved corrosion resistance and durability. Additionally, composite materials reinforced with GO support lightweight structural designs. These applications demonstrate how the material transitions from laboratory research to commercial products.

Manufacturing Advantages and Scalability

Manufacturing scalability plays a major role in material adoption. GO offers advantages in this area because it supports solution-based processing and bulk production methods.

Producers can control oxidation levels to tailor performance while maintaining consistency. This flexibility reduces cost and supports large-scale manufacturing. As production techniques continue to mature, GO becomes increasingly accessible for industrial use.

Environmental and Sustainability Considerations

Sustainability now influences material selection across industries. GO supports this goal by extending product lifespan and improving efficiency.

Longer-lasting coatings reduce maintenance needs. Improved energy storage efficiency lowers resource consumption. These indirect benefits support environmental objectives while maintaining performance standards. Therefore, graphite oxide aligns well with sustainable manufacturing strategies.

Future Possibilities

Research continues to expand the potential of graphite oxide. Scientists explore improved control of oxidation, hybrid materials, and multifunctional systems.

Future applications may include advanced filtration, smart coatings, and next-generation electronic devices. As demand for efficient and adaptable materials grows, GO will continue to play a central role in innovation.

Ending up Thoughts

Graphite oxide continues to shape modern energy, electronics, and coatings through its combination of structural versatility, high surface activity, and scalable processing. These properties support efficient charge transfer in batteries, improve signal reliability in electronic components, and enhance barrier strength in protective coatings. In addition, its layered structure enables strong interactions with polymers and metals, improving durability and mechanical stability in composite systems.

As research progresses, scientists are developing better control over oxidation levels and dispersion quality, leading to more consistent performance. At the same time, advances in manufacturing techniques are making large-scale production more practical and cost-effective.

Because of this steady progress, GO is expected to remain a key material for high-performance, reliable, and adaptable solutions that align with future technological and industrial requirements.