Selecting the right industrial partner is a critical decision for any manufacturing or logistics-driven business. When evaluating Conveyor System Manufacturers in India, buyers must look beyond pricing and focus on technical competence, customization ability, compliance standards, and long-term reliability. With India emerging as a global hub for industrial equipment manufacturing, making an informed choice can directly impact productivity, safety, and operational efficiency.

This technical checklist is designed to help procurement managers, plant heads, and operations teams systematically evaluate conveyor system suppliers and ensure the selected manufacturer aligns with both current and future requirements.

-

Understand Your Application Requirements Clearly

Before approaching any supplier, define the purpose of the conveyor system. Factors such as load capacity, material type, operating environment, speed requirements, and layout constraints must be documented in detail. Whether the system is meant for bulk material handling, assembly lines, warehousing, or packaging, a clear requirement brief allows manufacturers to propose technically sound solutions rather than generic systems.

Industry-specific needs—such as hygiene standards in food processing or corrosion resistance in chemical plants—should also be considered at this stage.

-

Evaluate Engineering and Design Capabilities

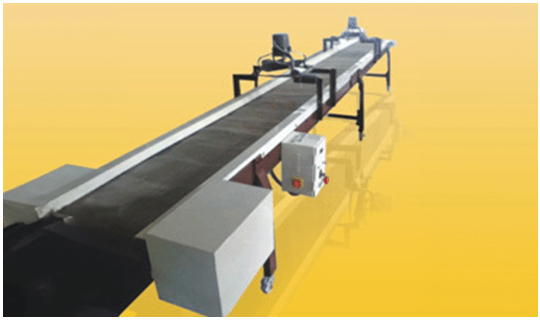

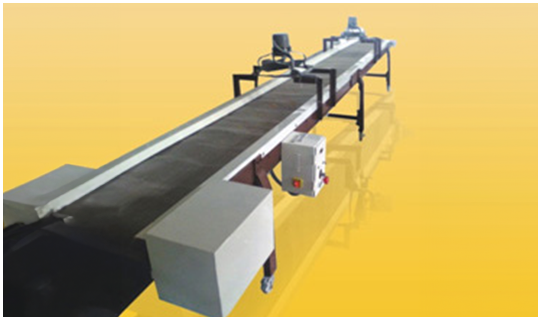

A reliable manufacturer should have strong in-house design and engineering expertise. This includes the ability to provide 2D and 3D layouts, load calculations, motor sizing, and structural analysis. Advanced manufacturers use modern design software and simulation tools to optimize system performance before fabrication begins.

Ask whether the manufacturer offers customized conveyor designs instead of one-size-fits-all products. Custom engineering often leads to better space utilization, reduced maintenance, and improved throughput.

-

Check Manufacturing Infrastructure and Quality Control

The quality of a conveyor system is directly linked to the manufacturer’s production capabilities. Well-equipped fabrication facilities, CNC machinery, precision welding, and proper surface finishing processes indicate a strong manufacturing foundation.

Equally important is quality control. Reputed suppliers follow strict inspection protocols at every stage, from raw material procurement to final assembly. Certifications such as ISO standards are a strong indicator of consistent manufacturing practices and process discipline. Additionally, consider future expansion. A well-designed conveyor system should allow modular upgrades or capacity enhancement without major structural changes, ensuring long-term adaptability which is available at the best Conveyor System Manufacturers in India.

-

Component Selection and Technology Integration

High-performance conveyor systems depend on the quality of components used—rollers, belts, chains, motors, gearboxes, sensors, and control panels. Buyers should confirm whether the manufacturer uses branded or tested components and complies with relevant industrial standards.

Modern conveyor solutions increasingly integrate automation features such as variable frequency drives (VFDs), PLC-based controls, and sensor-based monitoring. These technologies enhance efficiency, reduce energy consumption, and support future scalability.

-

Industry Expertise Matters

At this stage of evaluation, buyers often narrow down their options to experienced Conveyor System Manufacturers in India that demonstrate proven expertise across multiple industries. Experience translates into better problem-solving, faster commissioning, and systems that perform reliably under real-world operating conditions.

Manufacturers with a diverse project portfolio are more likely to anticipate challenges and recommend practical design improvements.

-

Installation, Testing, and Commissioning Support

A conveyor system’s performance depends heavily on proper installation and alignment. Choose a manufacturer that offers end-to-end support, including on-site supervision, testing, and commissioning. Choosing the right partner from among the many Conveyor System Manufacturers in India requires a structured technical evaluation rather than a price-driven decision.

Pre-dispatch testing, trial runs, and performance validation ensure that the system meets agreed specifications. Comprehensive documentation, including operation manuals and maintenance guidelines, further adds value during handover.

-

After-Sales Service and Maintenance Capability

Long-term support is often overlooked during procurement but is critical for uninterrupted operations. Evaluate the manufacturer’s ability to provide spare parts, breakdown support, and preventive maintenance services.

A responsive after-sales team, clear service agreements, and quick turnaround times can significantly reduce downtime and protect your investment over the system’s lifecycle.

-

Compliance, Safety, and Future Scalability

Industrial conveyor systems must comply with safety norms and local regulations. Features such as emergency stop mechanisms, guards, and load protection systems are essential for operator safety.

Conclusion

By focusing on engineering capability, manufacturing quality, component standards, service support, and scalability, buyers can invest in conveyor solutions that deliver consistent performance, safety, and return on investment for years to come.

Other Recommendations: Chocolate Cooling Tunnel Exporters