Mastering the Art of Fine Line Detailing

The precision of customization for cars is typically a game between millimeters and inches, in which the tiniest detail can make the most impact. When seeking high-end pinstriping tape, it is essential to consider flexible material and stability so that your lines remain sharp and professional. Every custom-designed project needs a unique approach to deal with curves, contours and different paint thicknesses without causing ugly bleeds or sharp edges. The effectiveness of your detail depends in the caliber and color that you use for the pinstriping tape.

Selecting Superior Materials for Longevity

The majority of modern detailing professionals prefer casting vinyl over calendered alternatives since it provides superior flexibility around complicated bodies and reflections. Top-quality pinstriping tape is usually designed to withstand intense UV exposure as well as harsh conditions of the weather conditions to avoid peeling or fading over time. When choosing your materials, be sure to select a product that is approved for use in the automotive industry to ensure it is able to handle chemicals in clear coatings. Selecting the best pinstriping tape guarantees that your hard work will not be damaged after a couple of car washes.

Understanding Width and Design Dynamics

The width of the decorative line could transform the look of your vehicle, shifting it from a traditional look to one that is modern and contemporary. A regular pinstriping stripe can be found in a variety of sizes, from ultra-thin 1/16-inch accents up to wider 1/4-inch bands, which mark the line of belts on the truck. Professionals typically use multi-stripe rolls, which have an “void” between two lines to produce a uniform double-stripe effect in a single application. Finding the right scale balance is the main reason for having various dimensions of pinstriping tape.

Precision Masking for Custom Paint Work

If you’re using the tape to mask a tool instead of a permanent decal, it is the heat resistance that becomes the most important factor in this curing phase. The specially designed striping adhesive made for painting masking is typically able to withstand temperatures of that exceed 250 degrees Fahrenheit, which makes it suitable for use in bake booths as well as dry cycles using infrared. This kind of tape has an adhesive with a low-tack that peels away without leaving a sticky remnant or lifting the base coat. For intricate flame patterns or geometric patterns, top-quality striping adhesive is a must to any professional shop.

Tackling Curves and Intricate Contours

One of the most challenging jobs in detailing is keeping the same line width traversing the sharp curve of a fender or motorcycle tank. Flexible pinstriping strip constructed from polypropylene, or more advanced PVC, lets the user extend and push the tape without the material snapping or tugging from the edges. Its “memory” in the material allows it to be affixed to it to the car’s exterior, which prevents paint from getting beneath the edge during spray application. It is possible to achieve an artistic look by mastering the tension needed to apply the high-stretch stripes.

Surface Preparation for Maximum Adhesion

Even the most expensive of adhesive products can fail when the surface of your vehicle is contaminated by grease, wax or silicones that are commonly found in sprays used for detailing. Before you apply to your striping adhesive, make sure you thoroughly clean the area with an oil and grease remover or diluted isopropyl alcohol solution. Clean, “squeaky” surface provides the molecular bonds required for the adhesive to stay to the clear coat or paint for many years. Doing the wrong thing can cause failure before the time of even the top-rated adhesive pinstripe.

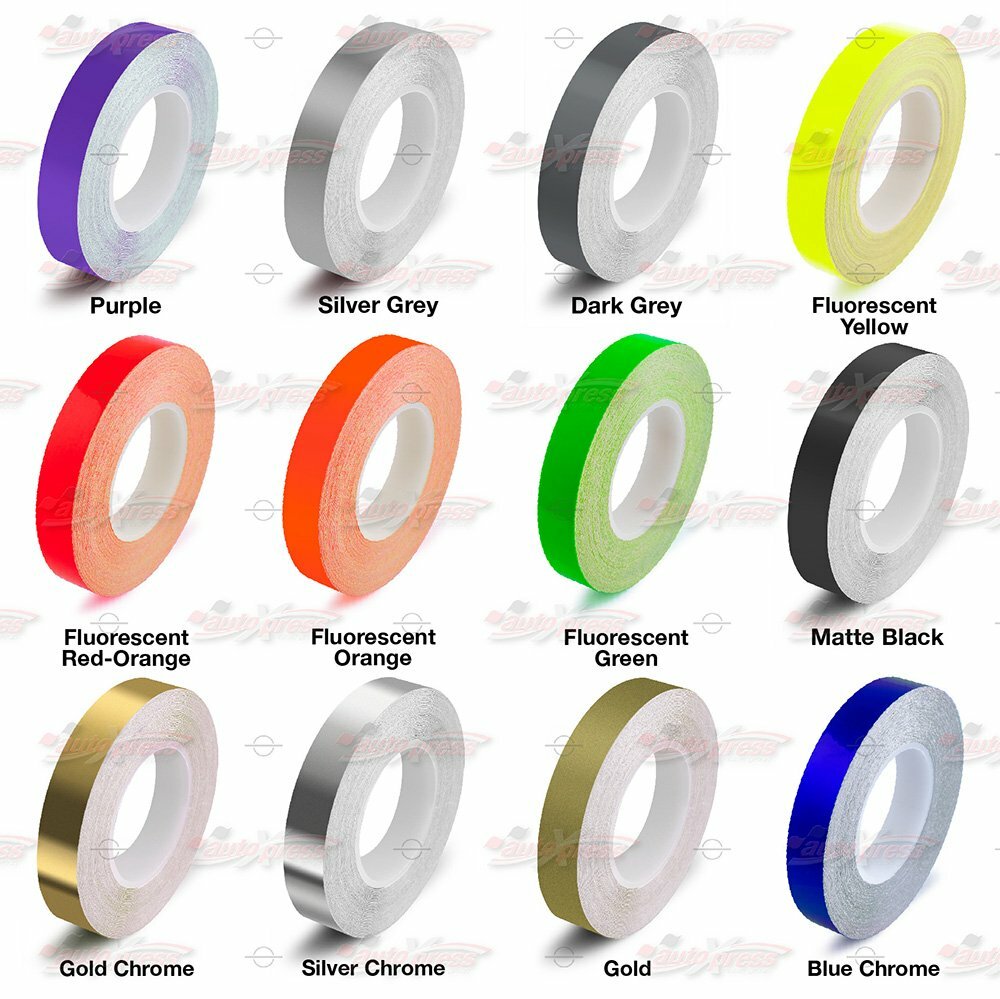

Color Coordination and Visual Impact

Picking a hue that matches or is in contrast with the primary paint scheme will be where an artist’s mind is truly at work for personalized details. The reflective stripes is now a popular option for emergency vehicles as it offers a level of security while also accentuating the silhouette of the vehicle in the dark. Pearlescent and metallic finishes can be used to replicate the appearance of high-end leafing or hand-brushed enamel, but without the expense of professional stripers. The visual quality of a design is usually determined by the color and finish of the selected striping material.

Achieving Seamless Overlaps and Finishes

At the point where you have reached the end of a line, how you finish the line may reveal if the task was performed by a novice or by an expert. A sharp knife for hobby is needed to cut pinstriping tape striping with an incline or a round point so that it is in line with a natural breaking line of a door’s jamb, or the hood edge. Detailers often choose to put the tape’s ends beneath a layer of clear coating to give a seamless, “under-glass” finish that is difficult to peel. Correct finishing techniques distinguish a regular application from an award-winning application of pinstriping tape.

Avoiding Common Detailing Pitfalls

One of the biggest errors novices make is stretching too much, which causes the material to “shrink back” and lift in the corners following just a few days of exposure to the sun. To prevent this from happening, put your striping adhesive down in a relaxed position and apply an easy squeegee, or pressure with a thumb to secure the edges with paint. If you spot bubbles, don’t attempt trying to push the tape upwards; instead, make use of a needle to let the air out and press it down. Be patient during the application process. is the key to a perfect result using the Pinstriping Tape.

Conclusion:

The right choice of adhesive and material type is the basis of any successful pinstriping project, whether for an old-fashioned restoration or a contemporary custom. Understanding the differentiators between the different types of vinyl, their sizes, and strengths, you can be sure of an attractive and durable end result that lasts for a long time. Keep in mind that the finest instruments are as effective as the process and preparation behind their use. Spending the time to choose an excellent pinstriping tape is the most effective choice that a detailer could make.