Forging has always played a major role in modern manufacturing. From aerospace parts to power plant equipment, forged components are trusted because they are strong, reliable, and built to last. Among the many materials used in forging, titanium forging is becoming more popular every year. Its strength, lightweight properties, and resistance to corrosion make it one of the most demanded materials for industries around the world.

In this blog, we will take a simple, easy-to-understand look at how titanium forging works, why it is so important, and how companies like CHW Forge ensure top-quality results. We will also discuss another important forged product — self reinforced nozzles — and how they support safe and efficient industrial operations.

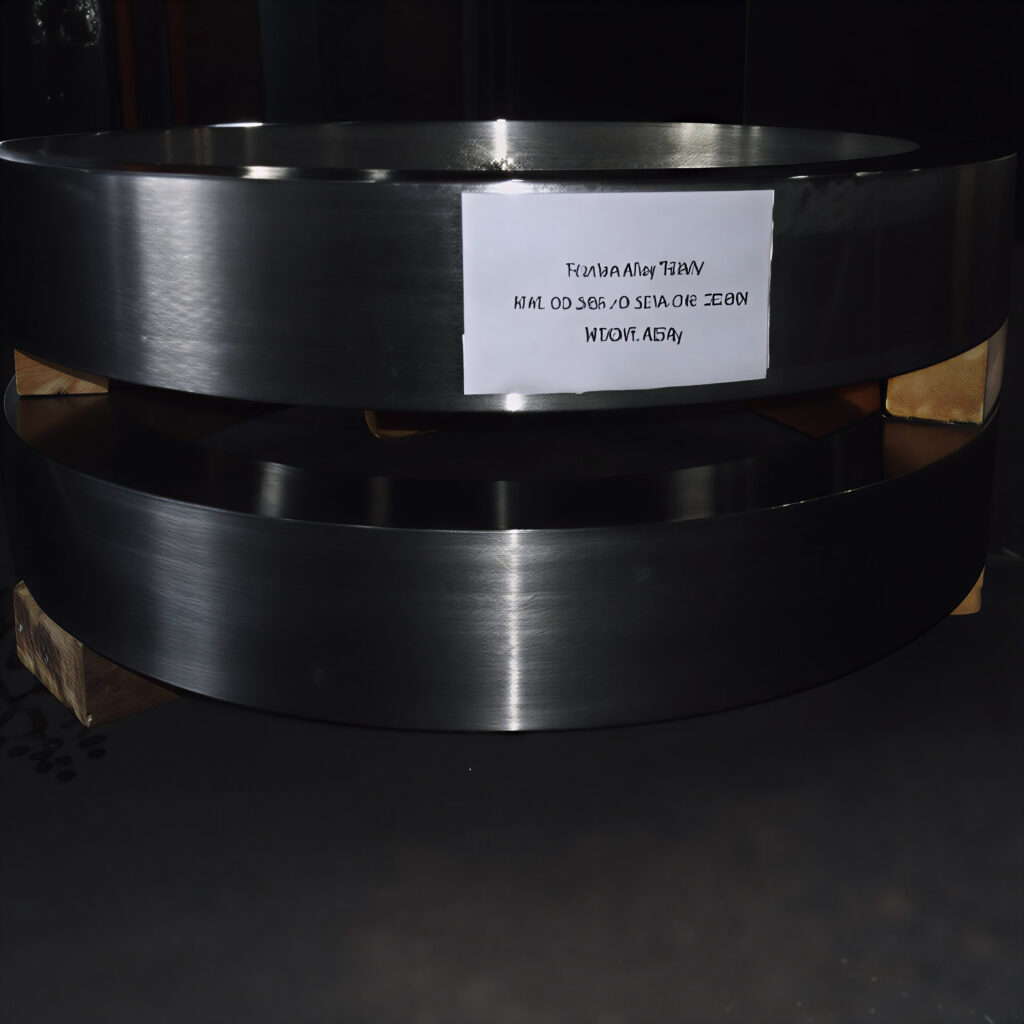

Understanding the Basics of Titanium Forging

Before we go deeper, it is important to understand what forging actually means. Forging is a process where metal is shaped using pressure. Instead of cutting or welding metal, forging compresses it into shape using hammering or pressing. This makes the metal stronger because the internal grain structure aligns in a better way

Why Titanium?

Titanium is a special metal because it offers:

- High strength

- Low weight

- Excellent corrosion resistance

- Ability to perform well in extreme temperatures

- Long service life

These qualities make titanium forging useful in industries like:

- Aerospace

- Defense

- Medical

- Marine

- Power generation

- Chemical processing

Forged titanium parts are able to handle stress, heat, and tough working environments better than many traditional metals like steel or aluminum. This is why titanium is often used for critical, high-performance components.

How the Titanium Forging Process Works

Even though titanium is strong, it is not easy to shape. It requires advanced technology, controlled temperatures, and skilled handling.

Here is a simple breakdown of the forging process:

Step 1 – Heating the Titanium

Titanium must be heated to a controlled temperature range. If it’s too hot, it becomes weak. If it’s too cold, it becomes difficult to shape. Maintaining proper temperature is the key to successful forging.

Step 2 – Applying Pressure

The heated titanium billet is placed under a press or hammer. This pressure shapes it into the required form. The metal flows uniformly, creating strong and stable components.

Step 3 – Cooling and Heat Treatment

After shaping, the titanium part is cooled in a controlled way. Sometimes, heat treatment is applied to give the component extra hardness or flexibility.

Step 4 – Finishing

The forged part is then machined to achieve the final shape, dimensions, and surface smoothness. At this stage, testing and quality checks also take place.

The result is a high-strength, durable component ready for use in tough industrial environments.

Advantages of Titanium Forging for Industrial Use

Forged titanium components offer several benefits over cast or machined parts.

1. Superior Strength-to-Weight Ratio

Titanium is strong like steel but much lighter. This is especially useful in aerospace, automotive, and marine applications where reducing weight can improve performance and fuel efficiency.

2. Excellent Corrosion Resistance

Titanium naturally resists corrosion from water, chemicals, and even salt environments. This makes titanium forging an ideal choice for offshore, chemical, and marine industries.

3. Long Service Life

Forged parts last longer because they are denser, stronger, and more stable. This reduces downtime and saves companies money in the long run.

4. Ability to Withstand High Temperatures

Titanium performs well in extreme temperatures, making it perfect for jet engines, power plant components, and high-pressure applications.

What Are Self Reinforced Nozzles and Why Are They Important?

Along with titanium forging, another important forged product used across industries is self reinforced nozzles. These nozzles are specially designed to handle high pressure and provide extra strength at the point where pipes or vessels need openings.

How Self Reinforced Nozzles Work

A self reinforced nozzle has added thickness around the opening, which strengthens the area and reduces the need for extra welding or reinforcement pads. This improves safety and performance.

Industries That Use Self Reinforced Nozzles

These nozzles are commonly used in:

- Oil & Gas

- Petrochemical plants

- Power generation

- Boilers and pressure vessels

- Chemical processing

Because they are forged, self reinforced nozzles offer better toughness and long-term durability than conventional welded nozzles.

How CHW Forge Delivers Superior Quality and Performance

Companies that rely on forged components cannot compromise on quality. This is where CHW Forge stands out. With decades of experience, advanced machinery, and strict quality standards, CHW Forge produces reliable titanium forgings and self reinforced nozzles that perform consistently in demanding conditions.

Commitment to Advanced Technology

CHW Forge uses:

- Modern forging presses

- Precision heat treatment

- High-quality testing equipment

- Skilled professionals trained in forging technology

These capabilities ensure every titanium forging and every self reinforced nozzle meets global standards.

Strong Quality Control

Every component is checked for:

- Strength

- Dimensions

- Surface quality

- Performance under pressure

- Integrity and safety

This strict inspection ensures customers receive parts that are ready to perform from day one.

Applications of Titanium Forging and Self Reinforced Nozzles in the Real World

Aerospace

Lightweight and strong titanium forgings are widely used in aircraft engines, landing gear, and structural components.

Oil & Gas

Self reinforced nozzles help maintain safety in high-pressure pipelines, vessels, and processing equipment.

Power Generation

Forged titanium parts ensure stable performance in turbines and boilers.

Chemical Industry

Since titanium resists chemicals, it is ideal for corrosive environments where long-term reliability is essential.

Why Choosing the Right Forging Partner Matters

Forged components are used in critical applications where failure is not an option. Choosing a reliable forging manufacturer is important for safety, efficiency, and performance. CHW Forge brings decades of trust, advanced technology, and global expertise to every project.

Whether you need titanium forging, self reinforced nozzles, or custom forged solutions, working with an experienced partner ensures you get strong, precise, and long-lasting components.