Fluid handling plays a crucial role in nearly every industrial process — from food and beverage manufacturing to chemical production and wastewater treatment. To achieve consistent, efficient, and contamination-free fluid transfer, industries rely on rotary lobe pumps. Known for their durability, gentle handling, and low-maintenance design, these pumps provide precise performance across a wide range of applications.

At JM Industrial, we supply a diverse selection of used and surplus rotary lobe pumps that deliver reliable performance and long service life. Each unit is inspected, tested, and ready for integration into existing process systems — offering the same dependable operation as new equipment, but at a much lower cost.

What Is a Rotary Lobe Pump?

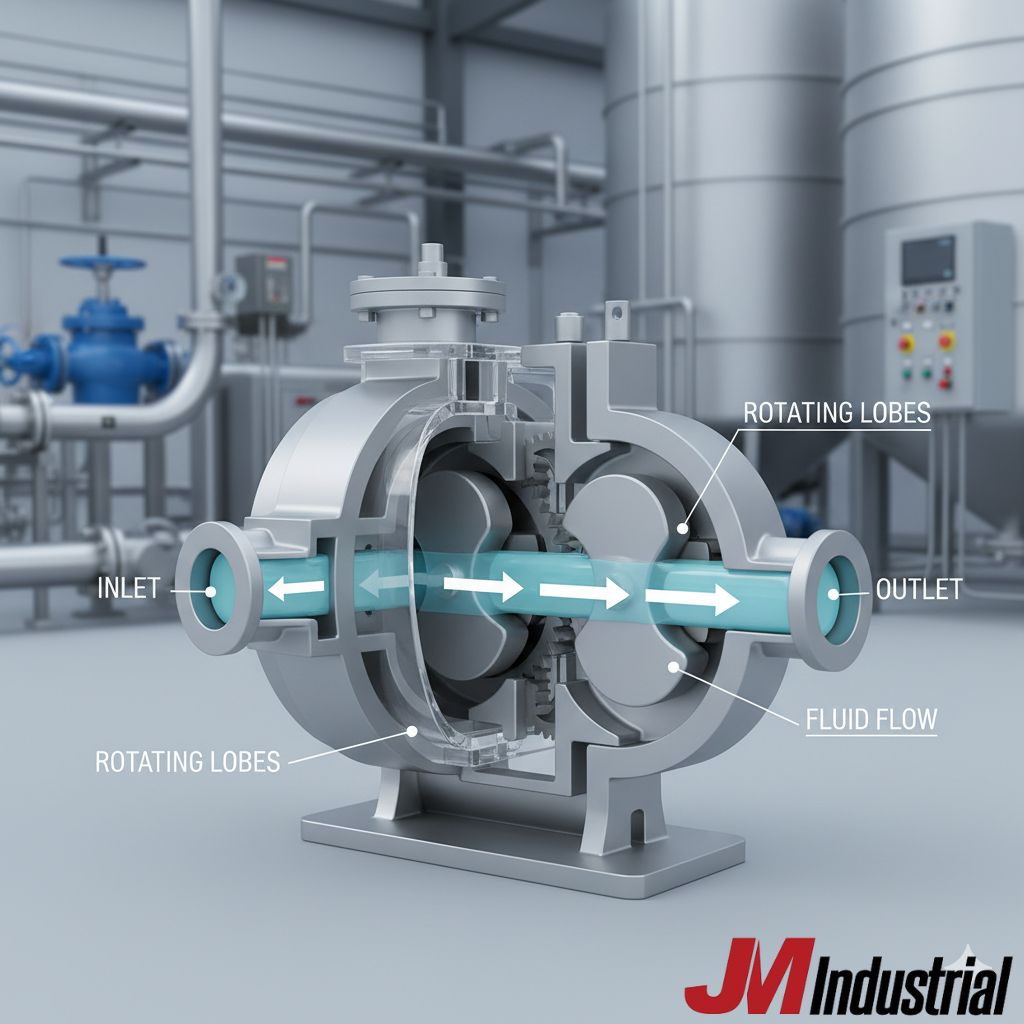

A rotary lobe pump is a type of positive displacement pump that uses two or more intermeshing lobes rotating inside a casing to move fluid. As the lobes rotate, they create cavities that trap liquid and carry it from the inlet to the outlet without compressing or damaging the fluid.

Because the lobes do not make direct contact with each other, rotary lobe pumps provide a smooth, pulsation-free flow and are suitable for both low and high-viscosity materials. This makes them a preferred choice for industries requiring gentle handling and hygienic transfer of sensitive fluids.

Working Principle of Rotary Lobe Pumps

The operation of a rotary lobe pump is based on the positive displacement principle. When the lobes rotate, they form expanding volumes on the inlet side that draw in fluid. The liquid is trapped between the rotor lobes and the casing, and as the lobes continue to rotate, it is carried around to the discharge side, where it is released under pressure.

The result is a consistent, non-pulsating flow that is ideal for precise metering and high-efficiency fluid transfer. Because the lobes don’t touch, the pump experiences minimal wear, reducing downtime and maintenance costs.

Key Features and Advantages

1. Gentle Product Handling

Rotary lobe pumps transfer fluids smoothly without excessive shear, making them ideal for delicate materials such as dairy, syrups, emulsions, and biological products.

2. Hygienic and Sanitary Design

Many rotary lobe pumps feature sanitary construction, including polished surfaces, clean-in-place (CIP) compatibility, and minimal dead zones — essential for food, pharmaceutical, and cosmetic processing.

3. Handles a Wide Range of Viscosities

These pumps can efficiently transfer both thin and highly viscous materials, from water to heavy slurries, without performance loss.

4. High Efficiency and Low Maintenance

With fewer moving parts and non-contacting rotors, rotary lobe pumps operate efficiently with minimal wear. This results in reduced maintenance costs and extended service life.

5. Reversible Flow Capability

Rotary lobe pumps can run in either direction, allowing for flexible system designs and easy clearing of process lines.

6. Robust Construction

Available in stainless steel and other corrosion-resistant materials, rotary lobe pumps are designed to handle abrasive, corrosive, and high-temperature applications.

Types of Rotary Lobe Pumps

JM Industrial offers a range of used rotary lobe pumps to suit various applications and flow requirements:

-

Single and Twin Lobe Pumps: Common for viscous or abrasive fluids.

-

Tri-Lobe Pumps: Provide higher flow rates and smoother operation.

-

Sanitary Lobe Pumps: Designed for food-grade and pharmaceutical use with hygienic certifications.

-

Heavy-Duty Industrial Lobe Pumps: Built for chemical, wastewater, and sludge-handling operations.

Each model in our inventory is tested and verified for performance, ensuring dependable operation even in demanding conditions.

Applications of Rotary Lobe Pumps

Rotary lobe pumps are highly versatile and serve multiple industries, including:

-

Food and Beverage: Transferring dairy products, sauces, juices, and syrups while preserving texture and quality.

-

Pharmaceuticals and Biotechnology: Moving gels, creams, and suspensions under sterile conditions.

-

Chemical Processing: Handling acids, polymers, and viscous chemicals with precision.

-

Cosmetics and Personal Care: Pumping lotions, creams, and shampoos with gentle consistency.

-

Pulp and Paper: Managing slurries, adhesives, and coatings.

-

Wastewater Treatment: Pumping sludge and viscous waste materials efficiently.

Benefits of Buying Used Rotary Lobe Pumps from JM Industrial

At JM Industrial, we provide cost-effective solutions for industries looking for reliable pumping equipment without the expense of new systems.

Why Buy from Us:

-

Thorough Inspection and Testing: Every unit is cleaned, inspected, and tested before sale.

-

Trusted Manufacturers: Our inventory includes pumps from reputable global brands.

-

Immediate Availability: Most units are in stock and ready for fast shipping.

-

Transparent Documentation: Complete specifications and operating data provided.

-

Cost Savings: Used and surplus pumps offer excellent value without compromising performance.

By choosing JM Industrial, you gain access to dependable rotary lobe pumps that meet the highest industrial standards.

Factors to Consider When Selecting a Rotary Lobe Pump

To ensure optimal performance and compatibility, evaluate the following before purchasing a pump:

-

Viscosity and Temperature of Fluid: Select the right pump type and material to handle your process conditions.

-

Flow Rate and Pressure Requirements: Match pump size and configuration to your system’s capacity.

-

Material Construction: Choose from stainless steel, cast iron, or other materials based on chemical compatibility.

-

Cleanability: For sanitary or food-grade processes, ensure the pump supports CIP/SIP cleaning.

-

Seal and Bearing Design: Opt for models that prevent leaks and handle abrasive media efficiently.

JM Industrial’s experts can assist in selecting a rotary lobe pump that aligns perfectly with your process requirements.

Maintenance and Best Practices

Proper maintenance helps ensure long-term, trouble-free performance:

-

Regularly inspect seals, bearings, and O-rings.

-

Maintain proper lubrication levels.

-

Keep the pump clean to prevent residue buildup.

-

Check alignment and coupling connections.

-

Replace worn components as needed to prevent downtime.

Following these steps improves reliability, efficiency, and pump longevity.

Why Used Rotary Lobe Pumps Are a Smart Investment

Buying a used rotary lobe pump from JM Industrial provides significant cost savings and dependable performance. These pumps are durable, low-maintenance, and engineered for long service life — making them a sustainable and economical choice.

With tested and verified equipment in stock, JM Industrial ensures fast delivery, proven reliability, and value-driven pricing — giving you complete confidence in your purchase.

Whether you need a pump for food processing, chemical handling, or wastewater management, our inventory of used rotary lobe pumps offers the right solution for your application.