When designing your custom butter paper layouts, you may find they have a great influence on the effectiveness of your bakery and the way your products are displayed. Fitting planning will help you to make your packaging functional and attractive. An efficient design can help save on wastage and ease transportation to the production stage. Proper positioning of graphics, text, and branding improves the consumer experience. Layout optimization is often ignored by bakers and packaging designers, but it impacts cost and workflow. The more you design your sheets strategically, the more you are able to align with fewer errors. This tutorial determines how to design the layout of custom butter paper with optimization. These tips lead to a quality presentation and consistency.

Sheet Planning

Planning on butterpapers is the first step to a good layout. I had to measure every sheet so that it would not tear or fold, but fit the baked goods. The correct arrangement of the branding elements will guarantee good visibility and minimize misalignment. The designers are advised to have some headroom for cutting and printing. Automation can be easily achieved by the consistency of size. The grid pattern can be used to ensure consistency over sheets. Planning the butter paper sheets carefully helps to save time and the cost of materials used in production.

Graphic Positioning

Good graphic positioning of the printed butter paper enhances its attractiveness. Logos, designs, and patterns must be oriented with the shape of the product. Artificial graphics may reduce the quality of baked products. Make sure that there is a good separation between designs, so that they can be easily folded or wrapped. The success of a visual presentation is determined by the use of repeatable patterns. Professional design software eliminates the possibility of printing errors. The brand recognition and satisfaction of customers increase because of attention to detail in the printed butter paper.

Material Handling

These involve material handling when laying down butter paper to bake. Heavy sheets have to be piled and inserted into printing/cutting machines properly. When it is not handled properly, this may result in wrinkles or uneven prints. The usability of the paper also depends on the storage conditions. Check that the sheets are clean and dry so they do not stick. There should be a list of steps to use when managing sheets by workers. Good management leads to waste minimization and increased speed in the production of butter paper to bake.

Roll Utilization

Using a butter paper roll can reduce waste, in addition to making the work of wrapping less challenging. Massive rolls should be cut to the right size of product. Proper utilization of rolls will eliminate over-cutting or under-cutting during production. Output consistency: roll intervals are marked. Tension and alignment achieved during printing enhance the overall results. To reduce errors, the staff should be trained on how to handle rolls. The correct roll management will enhance productivity for those businesses that use butter paper rolls in their daily operations.

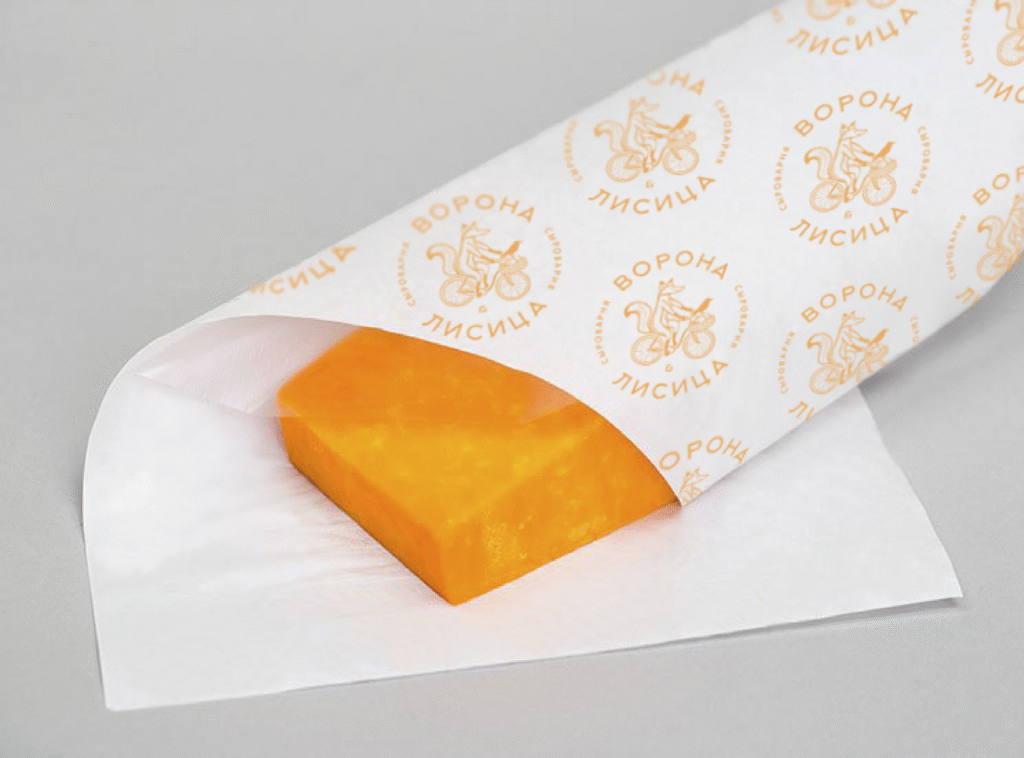

Branding Focus

One of the design considerations when creating custom printed butter paper layouts should be branding. The use of logos, slogans, or patterns will strengthen brand identity. Positioning must incorporate folding, stacking, g, and wrapping methods. There are visible graphics that keep a product attractive. The integration between branding anthe d functioning of packaging enhances perception among customers. Each sheet is a promotional resource for your business. It is advisable to ensure that custom-printed butter paper is optimized to present professionally and create a lasting brand impression.

Sheet Quality

Quality is very important when a butter paper sheet is used in layouts. Uniformity in thickness eliminates tearing or uneven wrapping. Glosses help enhance the print quality and minimize bleed. Quality Linen means that goods will be fresh and presentable. Check each batch prior to cutting or printing. Proper storing and processing increase the life of sheets. Premium butter paper sheet investment increases customer satisfaction as well as bakery efficiency.

Logo Integration

Using the right color of butter paper and logo improves brand awareness. Folding lines and visibility of the product will have to be taken into consideration in positioning. Do not overcrowd the graphics. Before starting the actual mass production, it is checked in the testing layout. Batch-to-batch consistency supports brand image. Employees must have a set of rules about placement. Usage of butter paper with logo creates a greater marketing effect.

Manufacturer Choice

When a good butter paper manufacturer is selected, the efficiency of the layout is guaranteed. A good supplier is one that offers the same sizes, quality materials, and options. Designs are optimized with the help of professional advice provided by manufacturers. They provide assistance in printing and cutting. Effective communication makes orders precise to the specifications. By liaising with an established butter paper manufacturer, time is saved and the quality of the product is enhanced.

Cutting Precision

It is crucial to cut Printed papers with logo correctly to bake with it. Sheets need to be cut to fit the baked goods to perfection. Skewed cuts may result in wastage of material or an uneven wrap. Having automated cutting machines limits human error and provides consistency. Marking lines helps the personnel when doing manual cuts. The visual effectiveness of final products is enhanced by proper cutting. Regular use of butter paper to bake means that every product will appear professional and attractive.

Conclusion

The layout optimization of the custom butter paper is necessary to ensure efficiency and the professional appearance of the bakery. The sheets and rolls are planned properly, and waste of materials is minimized. Branding is enhanced by graphic placement and integration of logos. Good sheets and good handling preserve the integrity of products. The collaboration with a reliable producer increases the efficiency of production. Strategic layout choices make wrapping procedures easier and enhance personnel workflow. Product differentiation is done through attention to detail. These practices will ensure high efficiency in operations and a high visual appearance.